International Filtration News • September 2023

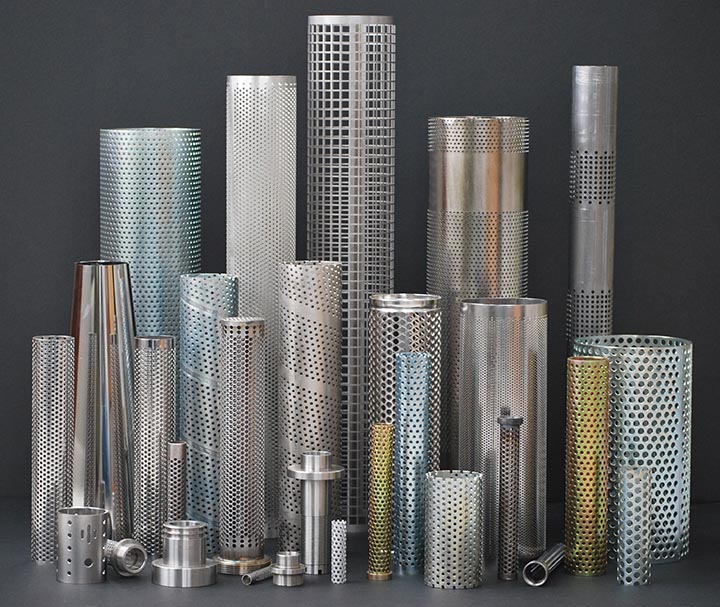

Beverlin’s focus is producing welded perforated cores and welded assemblies for filter manufactures. We are the recognized leader and have been since 1976.

Beverlin’s focus is producing welded perforated cores and welded assemblies for filter manufactures. We are the recognized leader and have been since 1976.

We have a global reach and provide many industries including Aerospace, Oil & Gas, Industrial, Power & Energy, Nuclear, Defense, Medical and Food & Beverage for the most demanding and critical applications. We take great pride in being the core that our customers build upon.

Benefits of a Welded Core

- The most obvious advantage is strength, a welded core is stronger for demanding high-pressure applications. We would argue that if it is a critical or demanding application where failure is truly NOT an option – a welded core is the best solution.

- Ability to use thicker material for demanding applications up to 1/8″ thick and even .157″ in some cases.

- Welded cores are not made from pre-plated materials like other cores. With pre-plated materials the holes, seam and edges are not plated.

- Welded cores are “flush” so there are no raised areas or raised seams. The flush seam allows the filter media to reach its peak potential.

- DESIGN FREEDOM – Not only are welded cores stronger and able to be thicker – there are many other advantages that most people have not considered.You can have any diameter, any length, any material type (steel, stainless, exotic alloys, aluminum or Titanium).

- You can pick any perforated pattern and add feature holes.

- You can have the seam style you want (straight or spiral).

- You can incorporate end margins (non-perforated areas).

- You can incorporate a counterbore.

- With a welded core you can use any surface treatment you desire vs. pre-plating of coil.

- With a welded core, we can produce any shape you need (round, triangle, rectangle, oval, etc.).

- Welded cores provide more design freedom so you can provide a more reliable and better performing core to better serve your customers and provide better solutions.

- With the design freedom of a welded core it can be made “unique” or custom making it difficult for someone else to recreate it. Your design could even be patented. That way the OEM can lock in their hard work and retain the ongoing sales for the long haul. That is huge!

Remember “if your part looks the same as everyone else’s, you will be competing with everyone else.”

Showcase for FiltXPO

Aside from our extensive standard offerings we will also be showcasing four categories.

- Our large diameter core offerings – more and more we are seeing the need for larger diameter cores that are 10’’, 12’’ and 14’’ and more.

- Examples of welded assemblies – we have been providing our customers with 100% complete welded assemblies including the core, CNC components, sleeves, posts, flanges and more which allows them to focus on a clean room type assembly.

- A new patented “seamless” technology with exceptionally tight tolerances that outperforms stainless steels in its mechanical properties and in corrosion while also providing holes as small as 80 microns – it will be a game changer for some applications.

- Offerings that include perforated cores and assemblies that are made from exotic super austenitic alloys like Hastelloy, Duplex, Super Duplex, Nickel 625, Nickel 825 and Titanium.

Visit us at FiltXPO: Booth #301